Imagine walking into a factory and finding serious safety violations-without any warning. That's exactly what the U.S. Food and Drug AdministrationThe federal agency responsible for protecting public health through regulation of food, drugs, medical devices, and cosmetics. does during unannounced inspections. Starting in May 2025, this surprise approach expanded to cover foreign manufacturers supplying products to the U.S. market. Here's why these inspections matter and what manufacturers need to know.

What Unannounced FDA Inspections Really Mean

Unannounced inspections are exactly what they sound like: FDA investigators show up at manufacturing facilities without prior notice. The main goal? To see operations as they truly happen, not how they look after days of preparation. This approach reveals real-time compliance issues that might be hidden during scheduled checks. For example, a facility might clean up a production line before a planned inspection but continue unsafe practices daily. The FDA uses these surprise visits to protect public health by catching problems early. According to the FDA's May 6, 2025 press release, "These inspections provide real-time evidence and insights that are essential for making fact-based regulatory decisions to protect public health."

The Big Shift: From Domestic to Global Surprise Checks

Before May 2025, the FDA treated domestic and foreign manufacturers differently. Domestic facilities typically faced unannounced inspections, while foreign factories often received weeks of advance notice. This created a "double standard" where foreign producers had time to prepare specifically for inspections, masking ongoing compliance issues. According to Sedgwick Blog data from June 10, 2025, when foreign facilities received advance notice, FDA still found serious deficiencies more than twice as often compared to domestic inspections. The May 6, 2025 policy change eliminated this discrepancy, ensuring all manufacturers-whether in the U.S. or abroad-are subject to the same surprise inspection rules. This move aligns with President Trump's May 5, 2025 executive order calling for enhanced oversight of foreign manufacturing facilities.

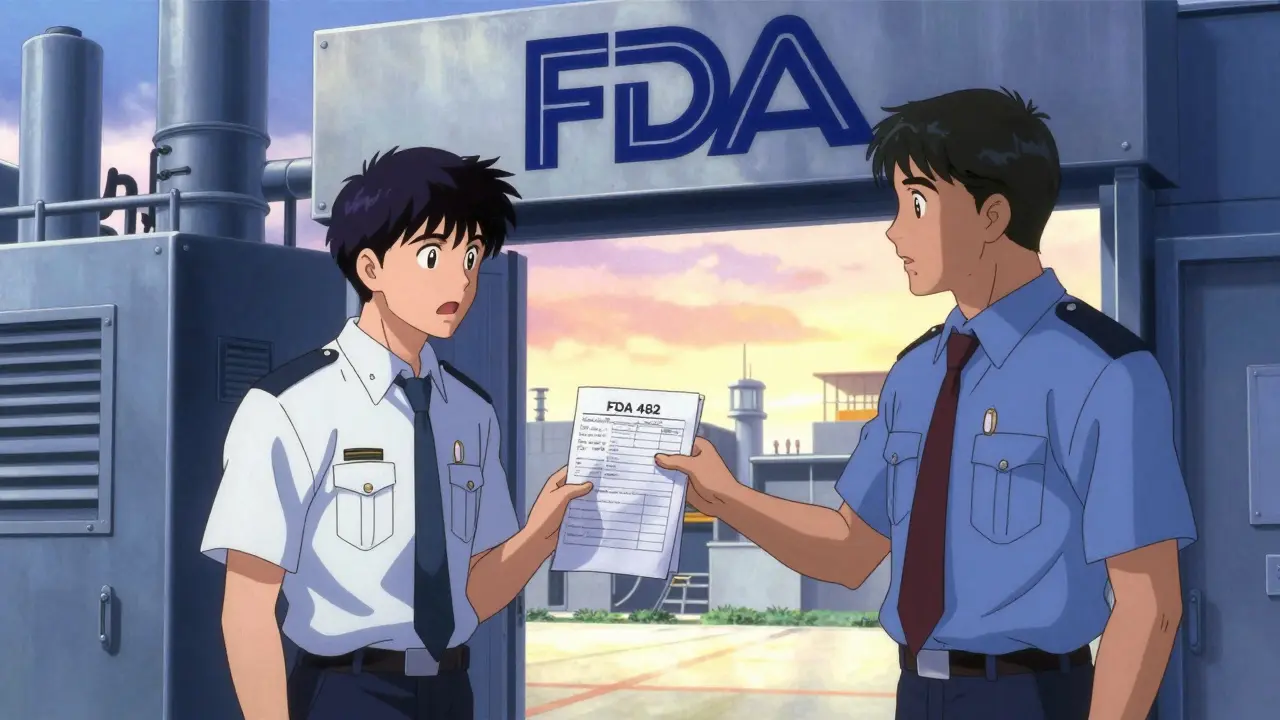

What Happens During an Inspection?

When FDA investigators arrive, they first identify themselves and show official credentials. They then issue Form FDA 482The official notice of inspection issued by FDA investigators during unannounced visits. to the facility's responsible person. This official document outlines the scope of the inspection and legal requirements for cooperation. The FDA's guidance states that Form FDA 482 is issued "to the most responsible individual available" and explains the inspection's purpose. Inspection duration varies based on the facility's size, complexity, and issues found. For medical device manufacturers, quality system inspections are always unannounced-unlike other types that might be scheduled. A typical inspection includes reviewing Standard Operating Procedures (SOPs), manufacturing records, and quality control data. The FDA classifies each inspection outcome, from "No Action Indicated" to major violations requiring corrective actions.

Why Foreign Factories Got the Same Rules

The FDA's expansion to foreign facilities wasn't arbitrary. In 2025, nearly 40% of finished drugs and 80% of active pharmaceutical ingredients consumed in the U.S. came from overseas. Yet foreign manufacturers often received advance notice-sometimes weeks ahead-to arrange translators and prepare documents. This gave them time to hide violations. McGuireWoodsA global law firm specializing in healthcare and regulatory issues. noted the FDA's position that "the move ensures that foreign manufacturers are held to the same standards and oversight as domestic companies." The change also aligns with President Trump's May 5, 2025 executive order to enhance oversight of foreign drug manufacturing facilities.

How Manufacturers Can Prepare

Manufacturers can't wait until the FDA knocks on the door. Experts like ParexelA global biopharmaceutical services company providing regulatory consulting and inspection support. recommend creating a clear response plan with designated personnel, immediate access to critical documents, and regular mock inspections. Greenlight GuruA company specializing in medical device quality management systems. emphasizes using QMS software with built-in compliance guardrails. "You won't always have time to duct-tape your legacy system tools before they walk through your door," they warn. Language barriers are another challenge-foreign facilities must now handle inspections without advance notice for translators. Bioprocess International documented a scenario where FDA investigators requested access to sterile manufacturing areas during an unannounced visit, testing immediate compliance capabilities.

The Bigger Picture: Global Supply Chain Safety

The FDA's expanded inspection program reflects growing scrutiny of global supply chains. With 80% of active pharmaceutical ingredients made overseas, ensuring quality is critical. FDA data shows that when foreign facilities received advance notice, over 90% of inspections found violations-compared to 45% for domestic facilities. The agency states this "expanded approach marks a new era in FDA enforcement-stronger, smarter, and unapologetically in support of the public health and safety of Americans." While questions remain about coordination with foreign regulatory bodies, the policy shift is permanent. For manufacturers, the message is clear: prepare for the unexpected, or risk losing access to the U.S. market.

Why does the FDA conduct unannounced inspections?

The FDA conducts unannounced inspections to obtain an authentic assessment of routine operations without the opportunity for facilities to prepare specifically for the inspection. This approach reveals the true state of compliance, helping to catch violations that might be hidden during scheduled checks. According to the FDA's May 6, 2025 press release, "These inspections provide real-time evidence and insights that are essential for making fact-based regulatory decisions to protect public health."

What happens during an FDA inspection?

FDA investigators arrive unannounced, show credentials, and issue Form FDA 482 to the facility's responsible person. They review Standard Operating Procedures (SOPs), manufacturing records, and quality control data. Inspection duration varies based on facility size and complexity. For medical devices, quality system inspections are always unannounced. The FDA then classifies the outcome, from "No Action Indicated" to major violations requiring corrective actions.

How do unannounced inspections differ for domestic vs foreign facilities?

Before May 2025, domestic facilities typically faced unannounced inspections, while foreign manufacturers often received weeks of advance notice. This created a "double standard" where foreign facilities had time to prepare specifically for inspections. The FDA's May 2025 policy change eliminated this discrepancy, ensuring all manufacturers-regardless of location-are subject to the same surprise inspection rules. This change addresses findings that serious deficiencies were found more than twice as often in foreign facilities when advance notice was given.

What should manufacturers do to prepare for unannounced inspections?

Manufacturers should create a clear response plan with designated personnel, immediate access to critical documents, and regular mock inspections. Using QMS software with built-in compliance guardrails is essential-"you won't always have time to duct-tape your legacy system tools before they walk through your door," warns Greenlight Guru. Companies should also address language barriers by ensuring translators are available or using digital tools for real-time translation during inspections. Regular audits and training ensure staff know how to handle unannounced visits without panic.

Are there any exceptions to unannounced inspections?

Yes, the FDA's official guidance states that "FDA inspections are generally unannounced, with a few exceptions" including specific programs where pre-announcement occurs to ensure appropriate records and personnel are available. For example, FDA typically conducts announced visits to facilities producing Class II or Class III medical devices every two years. However, "for cause" inspections or follow-up inspections are always unannounced. The FDA also coordinates with foreign authorities for some international inspections, though this practice is under review after the May 2025 policy change.

Unannounced inspections catch real-time issues that scheduled checks miss-critical for public health.

From my time in pharma, advance notice lets them hide issues. This change levels the playing field-foreign and domestic get the same surprise checks. Protecting public health, not just checking boxes.

Foreign factories getting the same surprise checks is a big deal. They used to have weeks to prep, which hid issues. Now they have to be ready anytime-good for safety, even if it's tough on them.

From my time in quality assurance, I've seen firsthand how scheduled inspections can be misleading.

Companies often have a 'show' ready for the inspectors, cleaning up everything just for the visit.

But with unannounced checks, there's no time to hide problems.

For example, last year at my plant, a scheduled inspection found nothing wrong, but a surprise visit a month later caught serious contamination issues in the production line.

It's not about punishing companies-it's about ensuring that the products we use every day are safe.

The FDA's move to apply this to foreign manufacturers is crucial because so much of our medicine and food comes from overseas.

Before this change, foreign facilities had weeks to prepare, which meant they could mask ongoing issues.

Now, they have to maintain compliance 24/7.

This is especially important for medical devices and drugs where even small lapses can lead to dangerous outcomes.

I remember a case where a foreign facility had perfect documentation during a scheduled inspection but was actually using subpar materials.

The surprise inspection revealed it immediately.

It's not just about the US market; it's about global health standards.

When companies know they can be inspected anytime, they're more likely to keep their processes clean.

This approach also helps prevent fraud, as there's no time to fabricate records.

Plus, it levels the playing field between domestic and foreign manufacturers.

Everyone has to play by the same rules.

The FDA's data shows that when foreign facilities got advance notice, over 90% of inspections found violations compared to 45% for domestic ones.

That's a huge gap.

By removing the advance notice, they're ensuring that all facilities are held to the same rigorous standards.

It's not easy for manufacturers, especially smaller ones, but it's necessary for public safety.

I've been in the industry for over a decade, and this change is long overdue.

Companies need to be prepared for the unexpected because that's the reality of the market.

It's not about fear; it's about responsibility.

If you're doing things right, you shouldn't have anything to hide.

This move will ultimately save lives and prevent crises before they happen.

The FDA is doing the right thing here-staying vigilant and proactive.

It's a small price to pay for safety.

Surprise inspections are just 'gotcha' tactics. Because nothing says 'we care' like showing up unannounced and expecting factories to have everything perfect on the spot. /s

lol yeah but like, if u r doin things right, no need to be scared of surprise checks. Maybe the companies hidin stuff should worry. But yeah, safety first.

US first foreign factories better get in line or get kicked out no more excuses safety non-negotiable

I see where you're coming from, but global supply chains are connected. Maybe work with foreign regulators instead of just threats. Safety's a shared goal.

Exactly! Collaboration beats threats every time. Safety first, always.